UHMWPE Sheet

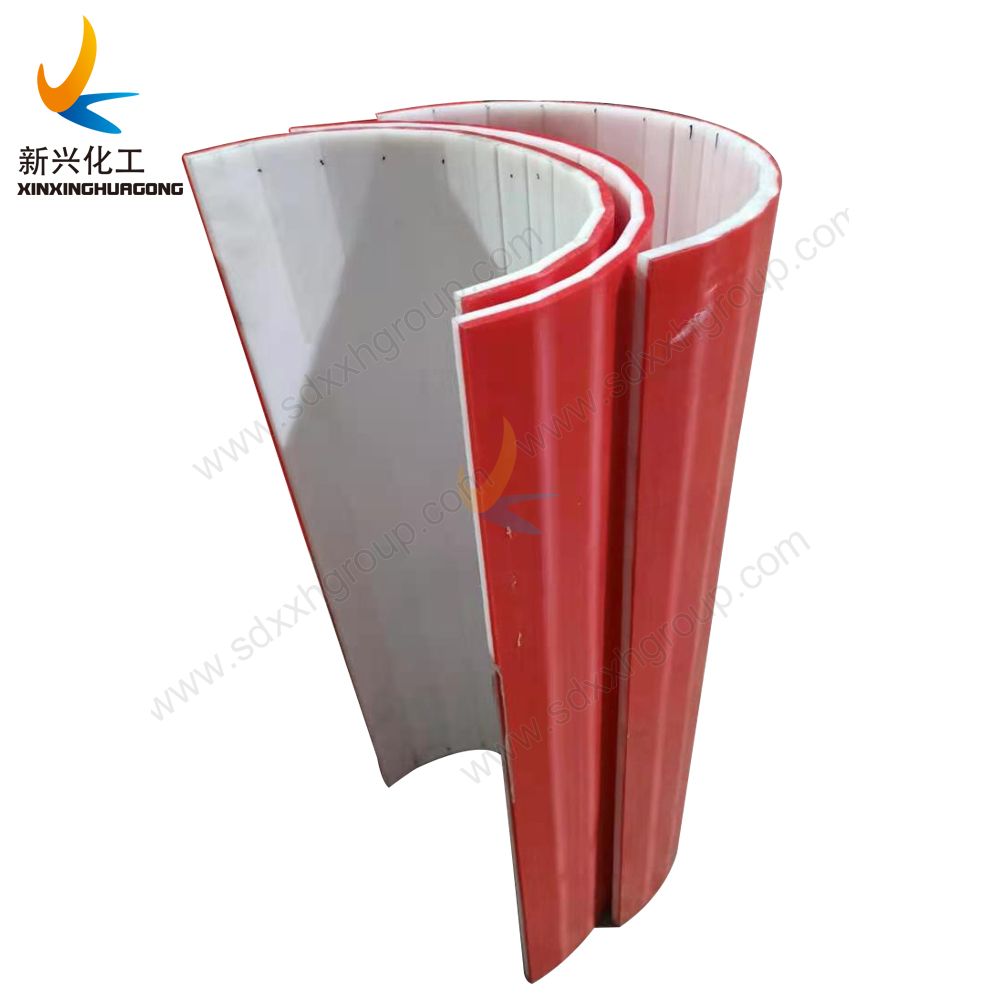

Home > Products > By Material > UHMWPE Sheet > abrasion resistant machinable plastic sheet PE1000 wear stripsUHMWPE marine fender are used mostly on the SCP Fender and Cone fender which are called the latest in state-of-the-art moulded fender products.The hdpe possesses a low coefficient of friction which provides a smooth sliding surface for the vessel to travel along the fender face.The following character also make the UHMW-PE Fender become the strongest and most popular fender in the world.

Here you can find all kinds of HDPE Sheet you want!

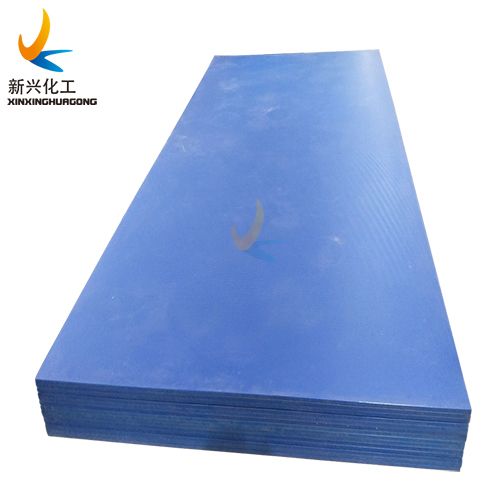

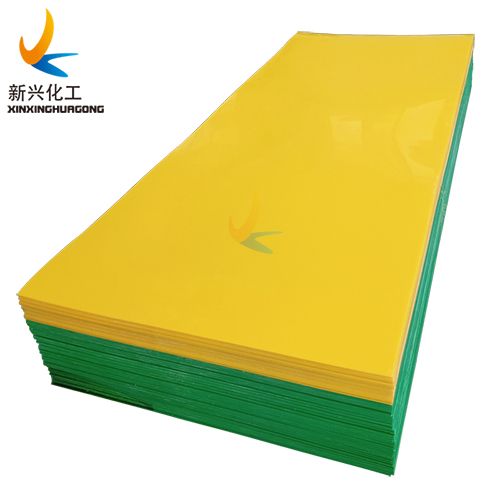

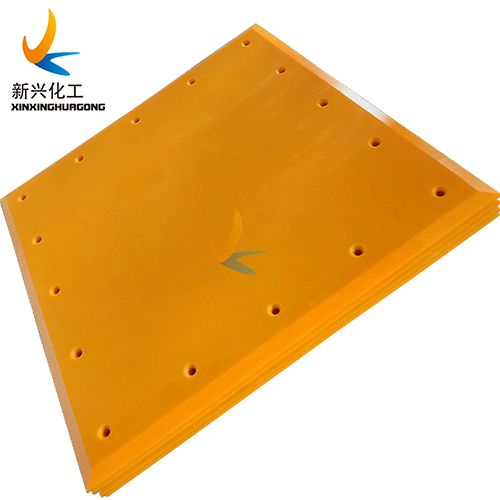

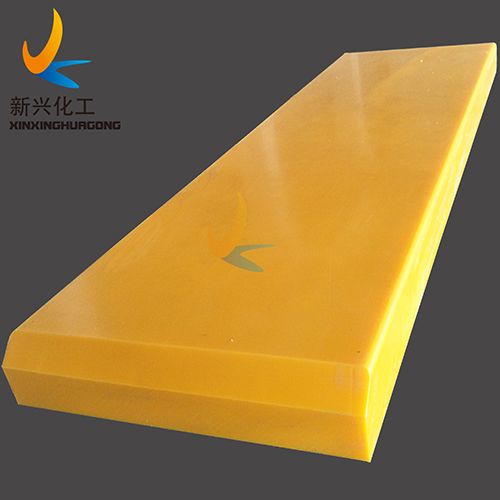

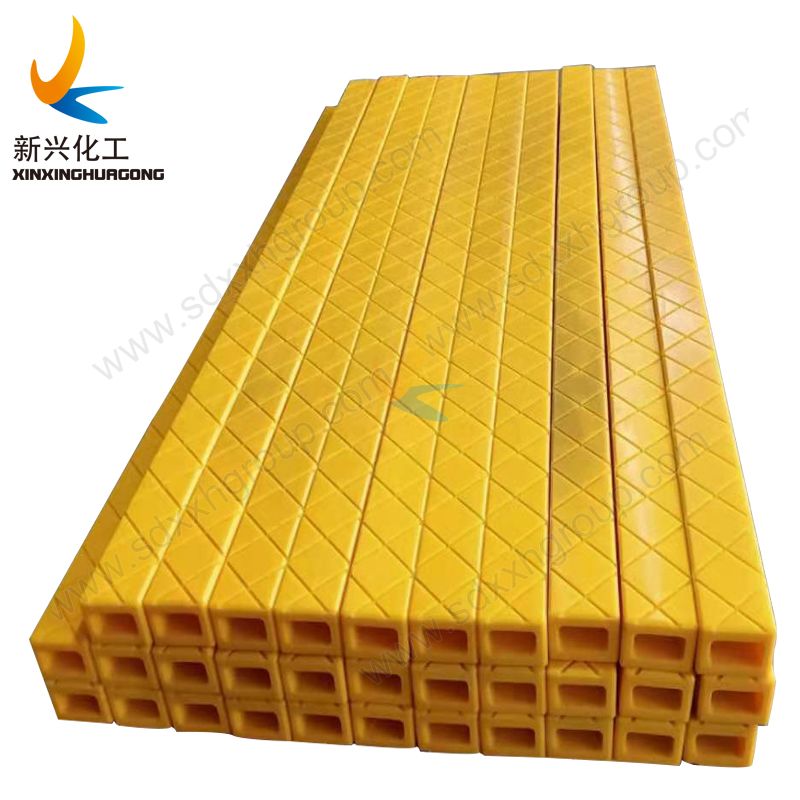

abrasion resistant machinable plastic sheet PE1000 wear strips

abrasion resistant machinable plastic sheet PE1000 wear strips

abrasion resistant machinable plastic sheet PE1000 wear strips

abrasion resistant machinable plastic sheet PE1000 wear strips

Advantages of UHMWPE sheet wear strips

The following character also make the UHMW-PE Fender become the strongest and most popular fender in the world

XINXING marine fender facing pad is made of HDPE/UHMWPE material

Because HDPE/UHMWPE material has the following advantage :

--Highest abrasion resistance of any polymer, 6 times more abrasion resistant than steel

--Do not absorb moisture and will not swell up over time due to exposure outdoors.

--Good impact intensity,Do not lose their impact strength over time.

--Good breaking elongation,so they will bend but not break under extreme loads.

--Non-stick surface, easy to clean.

--Corrosion and chemical resistant.

--Noise- absorption, Vibration-absorption

--Super compression strength

--15 Percent the weight of steel pads and easier to handle

--Compressive loads up to one million pounds

--Up to 15,000 pounds per square foot

--Non-Conductive

--Non-Toxic and smell

Benefits:

--Work in sub zero temperatures

--Easy to mount, replace

--Reduced downtime.

--Lower maintenance costs.

--Storage-Friendly

--Durable & Long Lasting

--Cost Efficient compared to Steel or Aluminum

--Safer to use in the field compared to other wood based pads.

Hdpe Specifications

| PROPERTIES | Test Method | Unit | Value |

| I.Physical Properties | |||

| Density | ISO 1183 | g/cm3 | 0.96 |

| Water absorption 24hrs | ISO 62 | % | 0.01 |

| II.Thermal Properties | |||

| Heat deflection temperature - HDT/A | ISO 75-2 | ºC | 42 |

| Min. service temperature | ºC | -269 | |

| Max. service temperature-Long Term | ºC | 90 | |

| Thermal conductivity at 23 ºC | DIN 11359 | W/(K*m) | 0.42 |

| Coefficient of linear thermal expansion | ISO 11359 | 10-4*K-1 | 2 |

| Flammability Rating(6mm thickness) | UL 94 | - | HB |

| III.Mechanical Properties at 23ºC | |||

| Tensile strength at yield | ISO 527-2 | MPa | 17 |

| Tensile strength at break | ISO 527-2 | Mpa | 40 |

| Elongation at break | ISO 527-2 | % | >50 |

| Modulus of elasticity after tensile test | ISO 527-2 | MPa | 650 |

| Modulus of elasticity after flexural test | ISO 178 | MPa | 800 |

| Hardness - Shore D | DIN 53505 | 61 | |

| Charpy impact strength | ISO 179 | kJ/m2 | N. B. |

| Friction coefficient | DIN 53375 | 0.25 | |

| IV.Electrical Properties at 23ºC | |||

| Dielectric constant at 1 MHz | IEC 60250 | 106Hz | 3.1 |

| Dielectric loss factor at 1 MHz | IEC 60250 | 106Hz | 0.0001 |

| Volume resistively | IEC 60093 | Ohm (Ω) * cm | >1014 |

| Surface resisively | IEC 60093 | Ohm (Ω) | >1011 |

| Dielectric strength | IEC 60243-1 | kV/mm | 45 |

| NOTE: 1 g/cm3 = 1,000 kg/m3, 1 Mpa = 1 N/mm2, 1kV/mm = 1 MV/m | |||

APPLICATION

⇒ Fender panel facing pads

⇒ Fender pile rubbing strips

⇒ UE-V fender shields

⇒ Facing strips for jetties and wharves

⇒ Lock entrance and lock wall protection

⇒ Mitres on lock gates

⇒ Bridge buttress protection

⇒ Pontoon pile guide bearings

⇒ Fast-launch lifeboat slipways

⇒ Beltings for smaller workboats

Top

+86 13173332640

Liaohe road, Ningjin county, Dezhou city, 253400, Shandong province, China.